製品の説明:

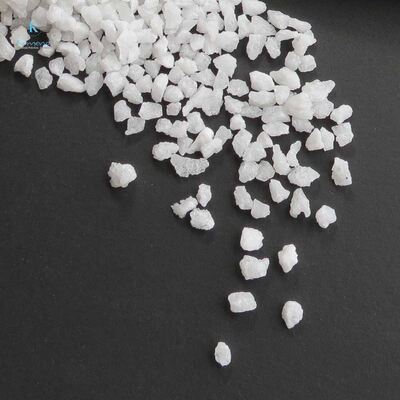

溶融アルミナとしても知られる溶融アルミナは、その優れた硬度と耐久性から、さまざまな産業用途で広く使用されている高品質な研磨材です。この製品は、独特の白から灰色の色を特徴とし、識別しやすく、さまざまな製造および加工環境に適しています。溶融アルミナの化学式はAl2O3で、その組成が酸化アルミニウムであることを示しており、その印象的な物理的および化学的特性で知られる化合物です。

溶融アルミナの密度は約3.95グラム/立方センチメートル(g/cm³)であり、研磨材としての堅牢性と有効性に貢献しています。この密度により、材料は大きな機械的ストレスと摩耗に耐えることができ、研削、研磨、ブラスト作業に最適です。また、高密度により熱安定性が向上し、構造的完全性を損なうことなく、極端な温度条件下でも良好に機能します。

溶融アルミナの最も注目すべき属性の1つは、モース硬度9であることです。これは、ダイヤモンドやその他の希少な物質を除き、利用可能な最も硬い材料の1つです。溶融アルミナの優れた硬度により、金属、セラミック、ガラスなどの硬質材料の切断、研削、仕上げに最適です。その研磨性により、効率的な材料除去が保証され、厳しい工業規格を満たす滑らかで正確な仕上がりが実現します。

溶融アルミナは、酸化アルミニウムを高温で溶融し、急速に冷却して緻密な結晶構造を形成する高温溶融プロセスによって製造されます。このプロセスにより、製品の純度と性能特性が向上し、異なる方法で製造される可能性のある他の形態の酸化アルミニウムとは区別されます。溶融プロセスにより、最終製品の不純物が最小限に抑えられ、均一な粒子サイズ分布が保証され、研磨用途で一貫した性能を達成するための重要な要素となります。

研磨品質に加えて、溶融アルミナは化学的に安定しており、腐食に耐性があるため、過酷な化学環境での使用に適しています。その不活性な性質は、酸、アルカリ、その他の化学物質と容易に反応しないことを意味し、工業環境での材料の寿命を延ばし、メンテナンスコストを削減します。この化学的安定性により、溶融アルミナは、材料が高温と攻撃的な化学物質への暴露に耐えなければならない耐火用途にも好まれる選択肢となっています。

溶融アルミナを一般的に利用する業界には、金属加工、自動車、航空宇宙、建設、エレクトロニクスなどがあります。金属加工では、精度と耐久性を必要とするグラインディングホイールや切削工具に使用されます。自動車および航空宇宙部門は、高い強度と耐摩耗性を必要とする部品の製造におけるその使用から恩恵を受けています。さらに、溶融アルミナは、優れた表面仕上げと厳しい公差を達成するために、セラミックおよびガラス製品の製造に使用されます。

研磨材を選択する際には、環境への配慮も重要であり、溶融アルミナは環境に優しいことで知られています。無毒であり、環境に害を及ぼすことなく安全にリサイクルまたは廃棄できます。これにより、高い生産基準を維持しながら、生態学的フットプリントを最小限に抑えようとする企業にとって持続可能な選択肢となります。

要約すると、溶融アルミナまたは溶融アルミナは、白から灰色の色、化学式Al2O3、密度3.95 g/cm³、および優れたモース硬度9を特徴とするプレミアム研磨材です。その優れた物理的および化学的特性により、幅広い産業用途に不可欠です。研削、研磨、または耐火目的で使用されるかどうかにかかわらず、溶融アルミナは信頼性の高い性能、耐久性、および効率性を提供し、現代の製造および加工技術における主要な材料としての地位を確固たるものにしています。

特徴:

-

製品名:溶融アルミナ

-

材質:酸化アルミニウム

-

外観:白から灰色の結晶性粉末

-

硬度:9モース

-

精密鋳造製品に最適

-

ブラウンコランダムとしても知られています

-

産業用途向けの高品質溶融アルミナ

-

耐久性と耐摩耗性に優れたブラウンコランダム材料

技術的パラメータ:

|

タイプ

|

ブラストメディア

|

|

主成分

|

酸化アルミニウム

|

|

材質

|

酸化アルミニウム

|

|

化学式

|

Al2O3

|

|

外観

|

白から灰色の結晶性粉末

|

|

硬度(モース)

|

9

|

|

粒子サイズ

|

2〜3mm

|

|

化学的安定性

|

酸性およびアルカリ性環境で安定

|

|

密度

|

3.95 G/cm³

|

用途:

KMNブランドの溶融アルミナ、型番Fは、その優れた硬度と化学的安定性から、さまざまな産業用途で広く使用されている高品質な研磨材です。ISO 9001の認証を受けており、この製品は一貫した品質と性能を保証します。モース硬度9、屈折率1.76のKMNの溶融アルミナは、主にAl2O3で構成されており、要求の厳しい研磨および耐火用途に最適です。

KMNの溶融アルミナの主な用途の1つは、研磨材製造です。業界ではブラウンコランダムとして知られており、研削砥石、サンドペーパー、ブラスト研磨材、研磨剤の製造に広く使用されています。その優れた硬度により、硬質金属やその他の材料を効率的に切断、研削、研磨することができ、優れた表面仕上げと工具寿命の延長を保証します。ブラウンコランダムの熱安定性も、耐熱性が重要な高速研削作業に適しています。

研磨材に加えて、KMN溶融アルミナは耐火用途でも重要な用途があります。その高い融点と化学的慣性により、炉、キルン、その他の高温処理装置のライニングの構成要素として一般的に使用されています。これにより、特に冶金、セラミックス、ガラス製造などの業界で、機器の耐久性と運用寿命が向上します。

このブラウンコランダム製品の汎用性は、セラミックスおよびエレクトロニクス業界にも及びます。その化学式Al2O3と硬度により、高度なセラミック部品、絶縁基板、耐摩耗性部品の製造に適しています。KMNの年間30,000トンの供給能力は、大規模な産業需要に対応するための信頼できる安定した供給源を保証します。

最小注文数量5トン、注文量に応じて価格交渉可能で、KMNは柔軟な購入オプションを提供しています。納期は注文数量によって異なり、支払い条件にはT/TおよびL/C at sightが含まれており、スムーズな国際取引を促進します。研磨材製造、耐火ライニング、または高度なセラミックスのいずれであっても、KMNの溶融アルミナは、厳格な工業規格と性能要件を満たす信頼できる材料です。

カスタマイズ:

KMNは、お客様の特定の要件に合わせて調整された、溶融アルミナ製品(溶融アルミナまたはブラウンコランダムとしても知られています)をカスタマイズして提供しています。当社のモデルFシリーズはISO 9001の認証を受けており、高品質と信頼性を保証します。最小注文数量は5トンで、ご注文サイズに応じて価格交渉が可能です。

この製品は、酸性環境とアルカリ性環境の両方で安定性を維持する安定した化学組成を特徴としており、精密鋳造製品に最適です。白から灰色の結晶性粉末の形で入手可能な当社のブラウンコランダム溶融アルミナは、高純度酸化アルミニウムから製造されています。

年間30,000トンの供給能力により、KMNはお客様の注文数量に応じてタイムリーな配送を保証します。支払い条件にはT/TおよびL/C at sightが含まれており、お客様に柔軟性と利便性を提供します。

よくある質問:

Q1:溶融アルミナのブランドと型番は何ですか?

A1:ブランド名はKMNで、型番はFです。

Q2:溶融アルミナ製品は認証されていますか?

A2:はい、ISO 9001の認証を受けています。

Q3:この製品の最小注文数量はどれくらいですか?

A3:最小注文数量は5トンです。

Q4:溶融アルミナの価格はどのように決定されますか?

A4:価格は、注文数量やその他の要因によって交渉可能です。

Q5:この製品の購入に利用できる支払い条件は何ですか?

A5:T/TまたはL/C at sightで支払うことができます。

Q6:注文の一般的な納期はどのくらいですか?

A6:納期は注文数量によって異なります。

Q7:KMNの溶融アルミナの供給能力はどのくらいですか?

A7:KMNは年間最大30,000トンを供給できます。

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!